Lithium-ion (Li-ion) batteries, composed of electrochemical cells, undergo calendar aging even when not in use. These degradation mechanisms must be carefully managed during storage to preserve battery health and safety.

This post examines these phenomena and their implications for storage protocols. We propose optimized storage strategies that balance operational costs with battery preservation.

We focus on the two most prevalent chemistries at the date of writing : NMC and LFP.

Degradation Mechanisms in Li-ion batteries during Storage

Three types of degradation occur during storage:

- A loss of stored charge in the battery (reversible phenomenon)

- Degradation due to excessive battery discharge, known as deep discharge (irreversible phenomenon)

- Calendar aging affecting the battery’s state of health (irreversible phenomenon)

Loss of charge

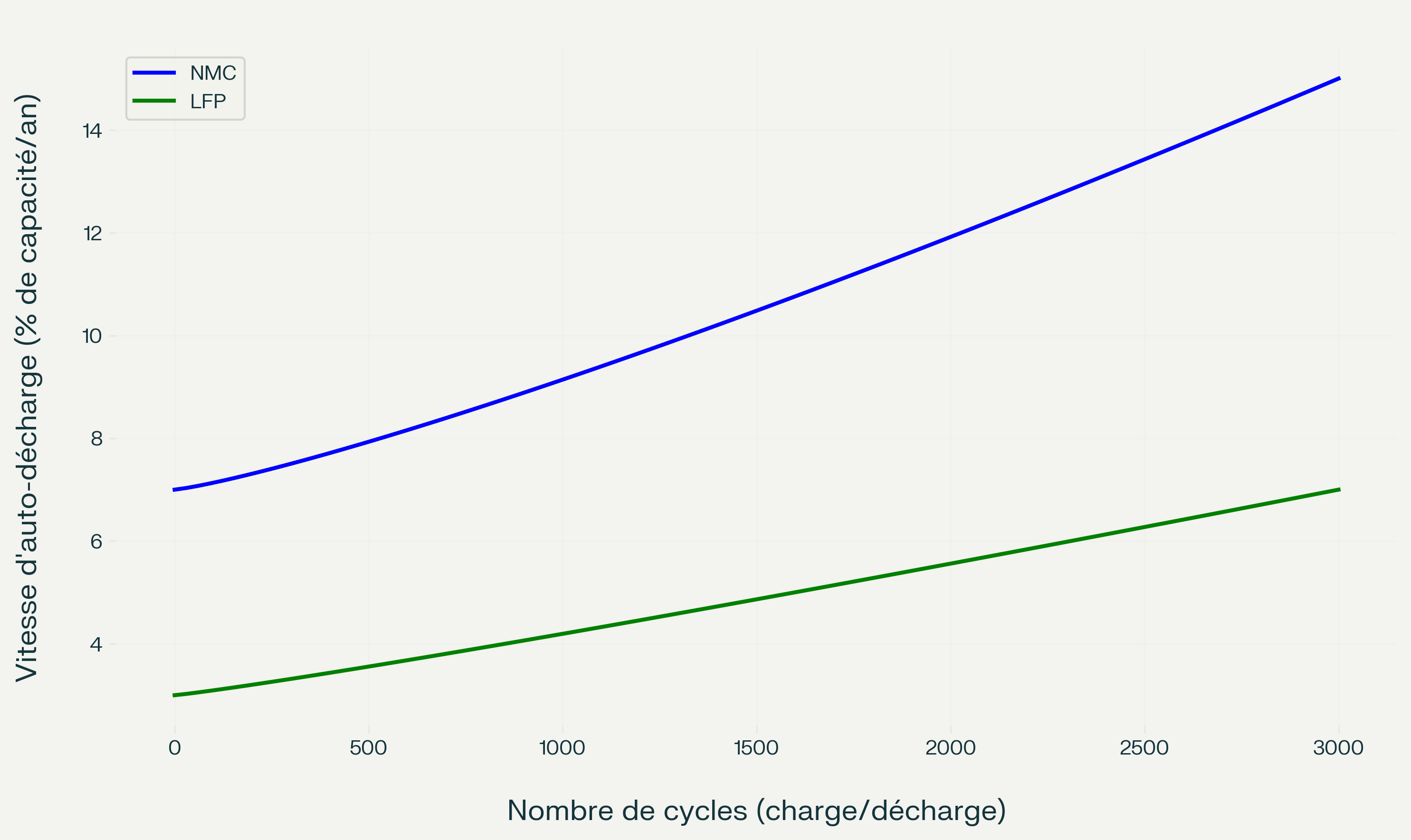

Due to various chemical phenomena, a portion of the energy stored in the battery can no longer be regenerated, resulting in a loss of the battery’s charge level, commonly referred to as SOC or State of Charge. Here are the self-discharge rates commonly observed in batteries :

| Chemistry | Charging loss at 25°C |

|---|---|

| NMC | Between 5% and 8% per year depending on cell type and condition |

| LFP | Between 2.5% and 3.5% per year depending on cell type and condition |

Note that the rate of charge loss is not stable over time for two reasons:

- Charge loss is faster during the first few months of storage for a new battery. This is because the battery cells are still in a chemical formation period

- Charge loss decreases over time as it depends on the battery’s charge level, which is diminishing

This phenomenon is not serious in itself since it is reversible through subsequent recharging of the battery. Nevertheless, it induces energy loss and, more importantly, without battery supervision, it can lead the battery to a deep discharge condition.

Deep discharge

A NMC or LFP battery cell requires maintaining a certain voltage between its terminals to preserve its solid-electrolyte interface (SEI) layer. This means that its discharge cannot fall below a certain level. This level is set as the 0% level of the SOC.

If the level drops below this threshold, the cell degrades. It may even present safety risks if reused.

This implies that a battery that has experienced deep discharge is irreparably damaged and must be sent for recycling.

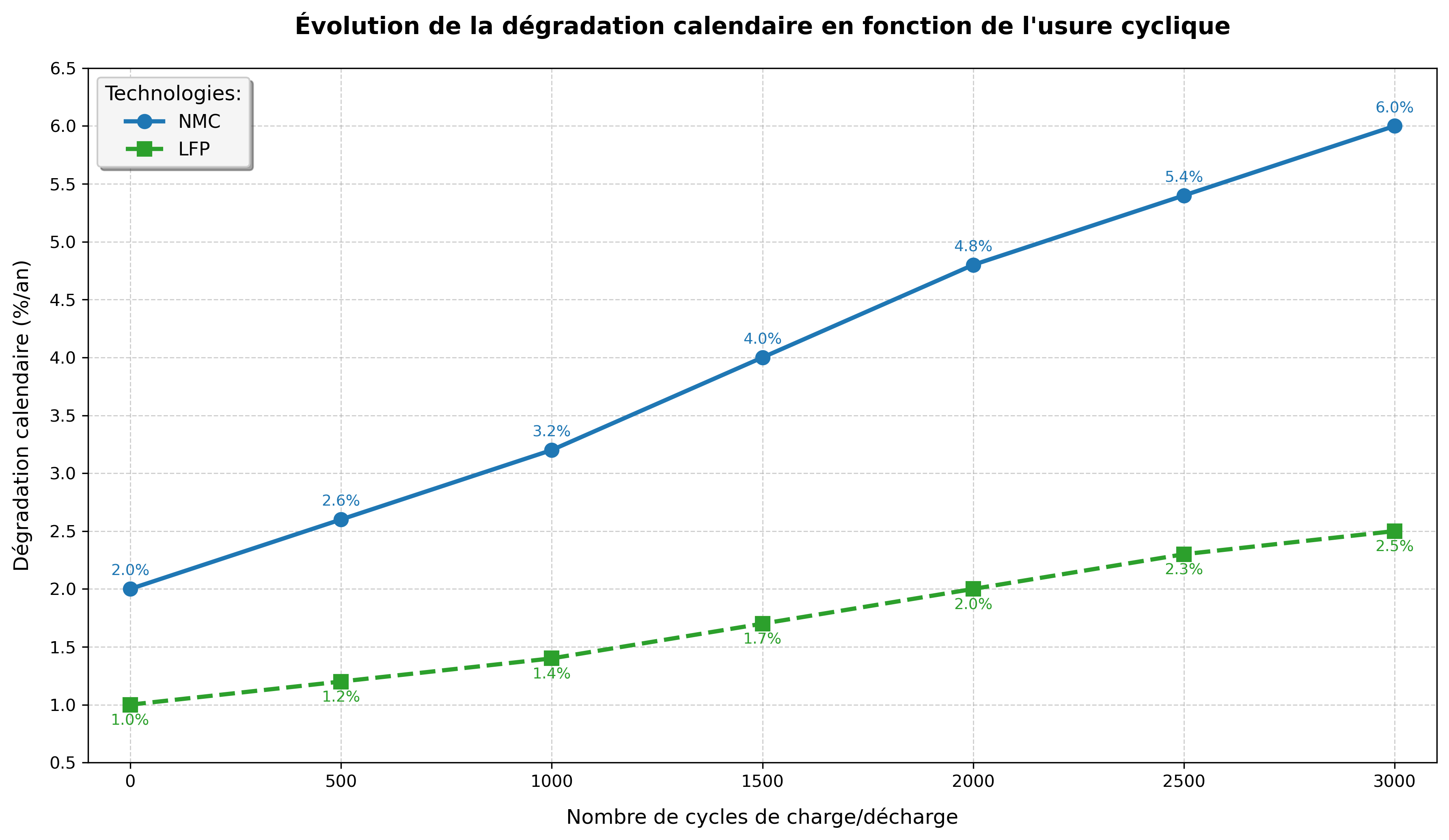

State of Health Degradation

Irreversible chemical reactions occur in the cells causing capacity loss over time, whether the batteries are used or not. The commonly encountered levels are as follows:

| Chemistry | Health loss at 25°C |

|---|---|

| NMC | Between 2.5% and 4% per year depending on cell format and type |

| LFP | Between 1% and 1.8% per year depending on cell format and type |

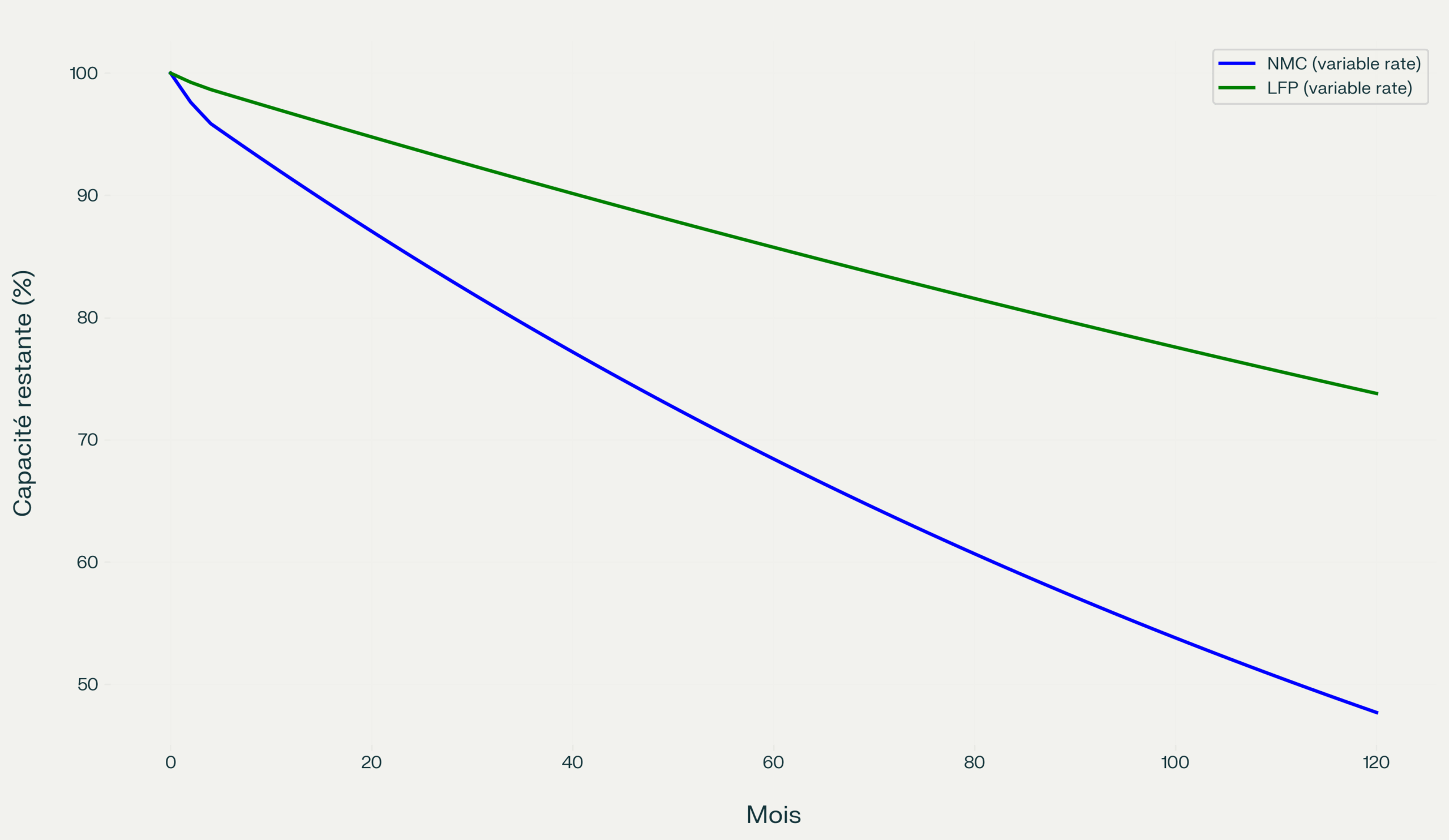

This capacity loss impairs battery performance, which will lose between 10% and 40% of its capacity during long-term storage. Its intrinsic value is therefore reduced accordingly

Parameters influencing degradation phenomena

Essentially 3 parameters affect the degradation speed of batteries.

Impact of battery wear

Battery wear is measured by the number of complete charge-discharge cycles. Generally, a battery’s lifespan consists of several thousand charge/discharge cycles.

As expected, battery wear negatively influences charge loss phenomena and health degradation.

At minimum, verification procedures and recharging protocols for batteries in long-term storage should be adapted according to battery wear.

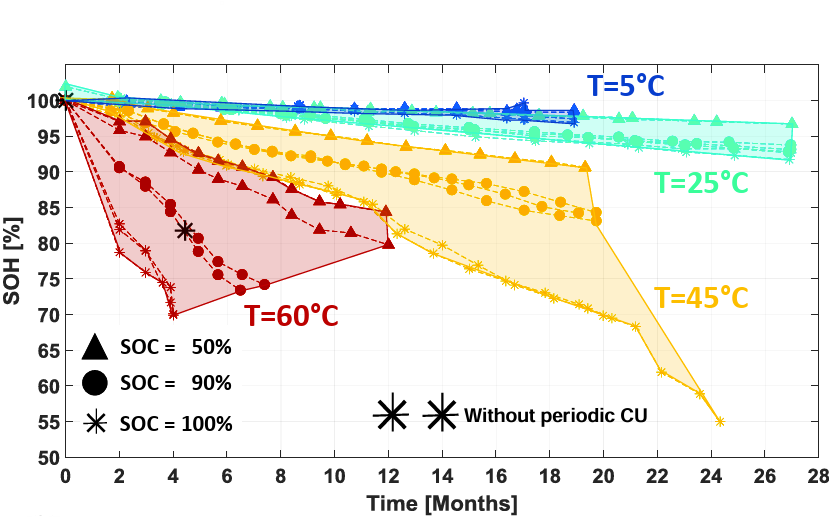

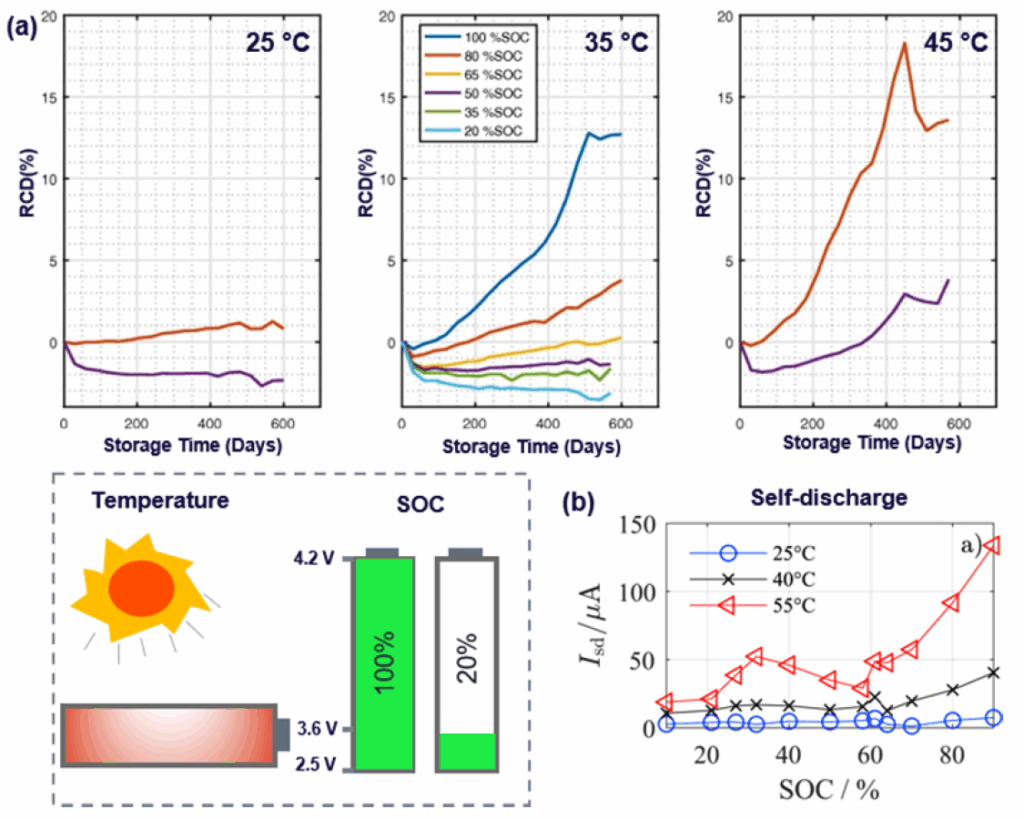

Impact of storage temperature

Storage temperature has a significant impact on battery degradation. The higher the storage temperature, the faster the degradation occurs.

This phenomenon is more pronounced for NMC cells, which are less stable at higher temperatures :

Therefore, batteries should be stored at low temperatures.

However, negative temperatures (< 0°C) should be avoided as they induce other types of cell degradation.

Impact of charge level

The battery’s charge level also has a significant impact on battery degradation. A low amount of stored energy, thus a low charge level, reduces the rate of degradation.

Battery safety

In the event of a battery incident (physical impact, thermal shock, defect, etc.), combustion phenomena or even explosion will have an intensity proportional to the battery’s charge level.

It is therefore preferable to store batteries at low charge levels to reduce risks.

Commonly used storage conditions

The conditions commonly encountered for NMC or LFP batteries are as follows :

- previously used batteries separated from new batteries

- Initial battery charge : between 30% and 50%

- Maximum battery charge for safety purpose : < 30% (incompatible)

- Storage temperature : between 15°C et 25°C

- Regular verification interval (every 1, 2, or 3 years) of charge level with potential recharging

These conditions represent a compromise between storage costs and battery degradation. The required storage temperature nevertheless necessitates a climate-controlled warehouse, which is not typically found, for example, in automotive parts storage facilities.

Process Improvement

Réduction de la charge initiale

Reducing the charge to a range between 5% and 25% (rather than 30%-50%) reduces degradation at all levels :

- Charge loss is slower at low charge. Annual charge loss is approximately halved for both NMC and LFP cells. This means intervals between recharges can be extended.

| Number of warehouse recharges reduced by half |

- With low charge, the impact of any potential thermal runaway is limited

| Safety criteria met, improved safety |

- Lower charge reduces wear phenomena

| Irreversible wear reduced by a factor of 2.5 |

Active Battery Monitoring

Battery monitoring helps prevent equipment losses. The new reference range approaches 0% charge, which leaves less margin and time to detect batteries nearing a deep discharge state.

To definitively avoid this risk, regular and automatic measurement becomes necessary.

| Automatic monitoring prevents the risk of deep discharge |

Furthermore, automatic monitoring also allows recharge intervals to be adapted to each battery. This is particularly valuable for optimally managing batteries with varying states of wear.

| Monitoring enables storage of batteries with any level of wear together |

Conclusion

Transitioning to a charge range of 5 to 25% during storage coupled with battery monitoring reduces the wear of stored Li-ion batteries while minimizing any necessary recharge periods.

Even if maximizing battery wear reduction is not necessarily an imperative objective, it can complement cost optimization measures for battery management. Thanks to the optimization indicated above, it also becomes possible to reduce storage temperature requirements, which means lower air conditioning/heating costs.

Annex : reference documents

- Reversible Self-discharge of LFP/Graphite and NMC811/Graphite Cells Originating from Redox Shuttle Generation

- Analysis of Lithium-ion Battery Cells Degradation Based on Different Manufacturers

- Étude du vieillissement des batteries lithium-ion dans les applications ”véhicule électrique” : combinaison des effets de vieillissement calendaire et de cyclage